Heat pipes are passive, two-phase heat transfer devices that offer highly effective thermal conductivity where more cooling is required than standard air-cooled heat sinks can provide. Because a heat pipe is a two-phase thermal transfer system, the thermal conductivity varies with length. A heat pipe thermal conductivity is considerably higher than that of solid metal, such as copper or aluminum, of the same size.

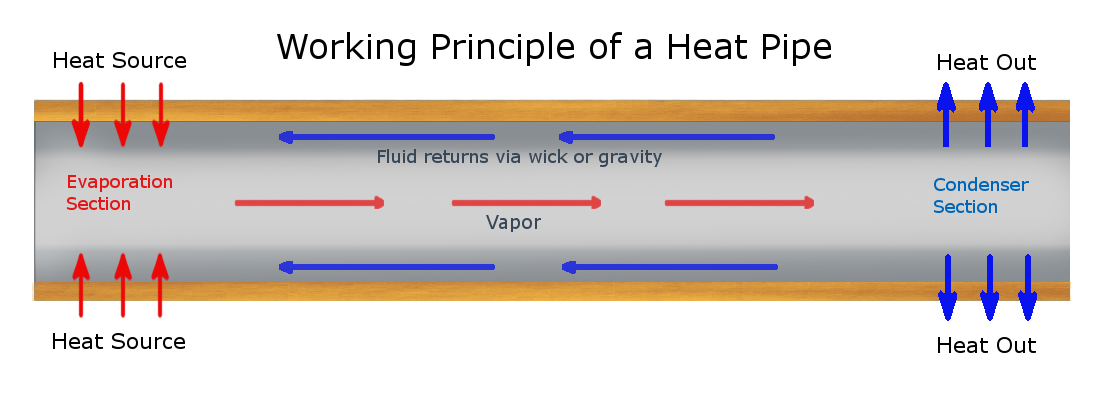

A heat pipe consists of a metal envelope, which is sealed under vacuum. Inside is a wick that contains a prescribed amount of fluid when the heat pipe is not in operation. When a heat source is applied along any section of the heat pipe (condenser section), the fluid vaporizes, which creates pressure. This pressure pushes the vapor to a cooler part of the heat pipe, where it transforms back to a liquid state. Capillary action from the wick passively pumps the fluid back to the condenser section to continue the process. When the condenser is above the evaporator (on earth), gravity will return the liquid to the evaporator.

The process will continue as long as there is a large enough temperature difference between the evaporator section and the condenser section. The temperature difference is dependent on the fluid that is used.

When are heat pipes used?

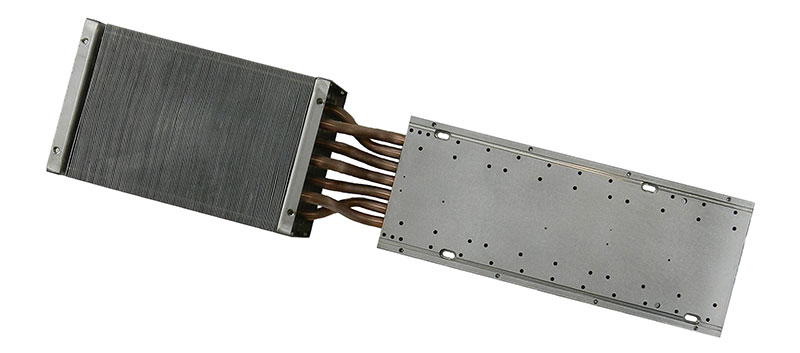

Heat pipes work well where there isn’t enough space to remove heat. In these cases, a heat pipe can move the heat to a heatsink or fin stack that is located in another area of the device.

Heat pipes can also be embedded into the base of a heat sink or cold plate to increase the heat footprint of a device. This makes cooling the device easier.

What materials are used for heat pipes?

When designing a heat pipe, the working fluid, wick, and envelope must be compatible, or an unwanted chemical reaction may occur. The materials used will also depend on the application. For example. electronics cooling is usually achieved with cupper-water or copper methanol systems. Aluminum ammonia systems are often used in aerospace. Working with a knowledgeable heat pipe manufacturer will ensure your heat pipe continues to work properly for a long time.

Learn How KTK Can Help

To discuss your project with our engineer and learn if a heat pipe will work for your heat transfer challenge, contact us.